产品特征

2.2~45kW 四级,二级 50Hz:1450rpm

绝缘等级:F

防护等级:IP68

水温:0~40℃

电源:三相380V±10%,50Hz

最大流量:402m³/h

最高扬程:45m

电缆长度:8米

应用工况:

水底采沙、河底池塘清於、清理沉淀池、工程施工抽排泥沙水、矿山作业面排水工矿企业抽送含有石英砂、煤泥、矿碴等磨料的污水

■ QW潜污泵QT/QNS泥砂泵产品简介

适用于化工、石油、制药、采矿、造纸工业、水泥厂、炼钢厂、电厂、煤加工工业,以及城市污水处理厂排水系统、市政工程、建筑工地等行业输送带颗粒的污水、污物,也可用于抽送清水及带腐蚀性介质。

QW潜污泵QT/QNS泥砂泵在引进联邦德国ABS制泵公司先进技术的基础上,在经我公司科研人员的共同努力下,同时广泛征求国内水泵专家的意见,并经过多次改良而研制成功的,经测试各顶性能指标均这到国外同类产国的先进水平。流量:7~2400m3/h,扬程:7~60m等,根据使用介质,安装方式不同设计制造成同性能参数的WL、YW、GW系列产品。

■ QW潜污泵QT/QNS泥砂泵产品特点

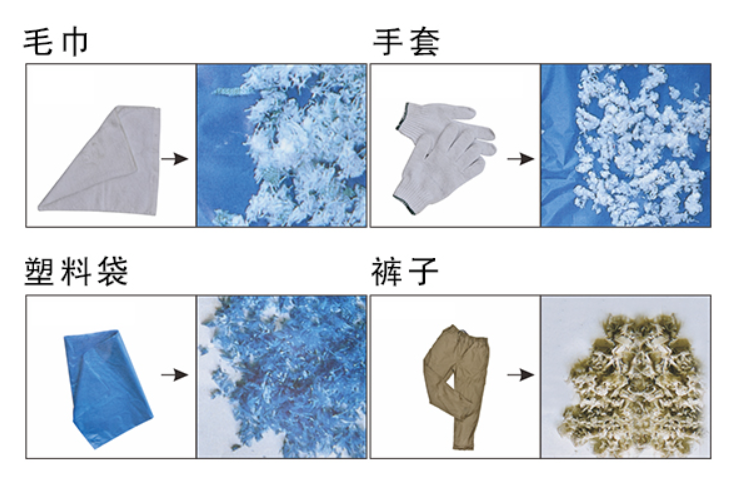

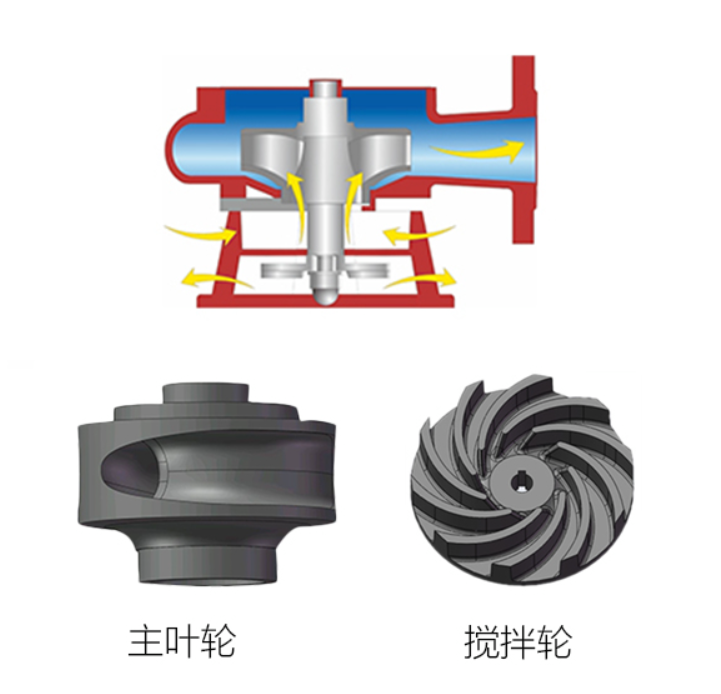

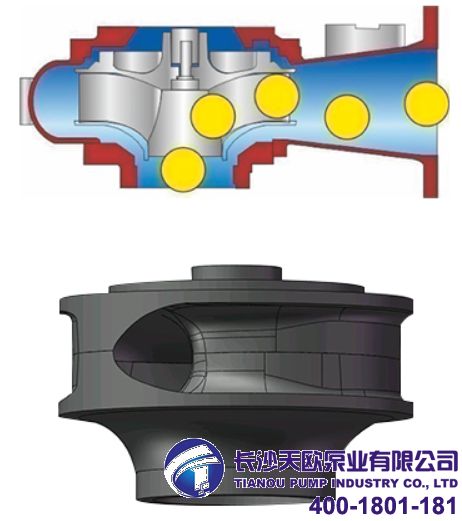

1.采用独特的单片或双叶片时轮结构,大大提高了活物通过能力,能有效的通过泵口径的5倍纤维物质与直径为泵口径约50%的固体颗粒

2.机械密封采用新型硬质耐腐的软化钨材料,可使泵安全连续运行8000小时以上。

3.整体结构紧凑、体积小、噪声低、节能效果显著,检修方便,无需建泵房,灌入水中即可工作,大大减少工程造价

4.该泵密封油室内设置有高精度抗干扰漏水检测传感器,定子绕组内预埋了热敏元件,对水泵电机自动保护。

5.可根据用户需要配备全自动控制柜,对泵的漏水、漏电、过载及超温等进行自动保护,提高了产品的安全性与可靠性。

6.浮球开关可以根据所需液位变化,自动控制泵的起动与停止,不需专人看管,使用极为方便。

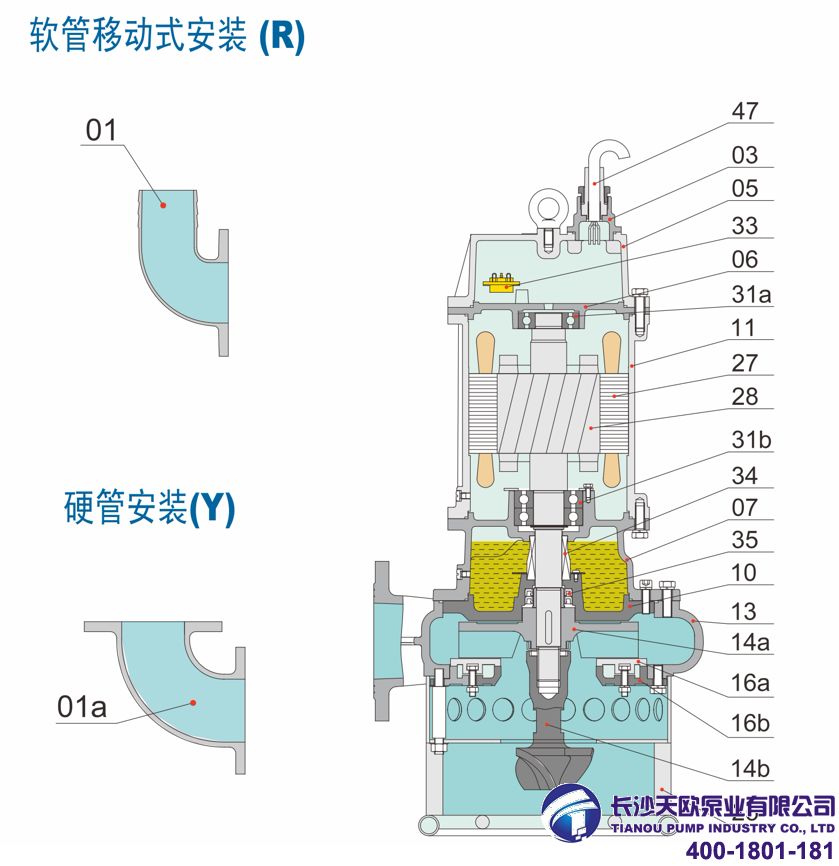

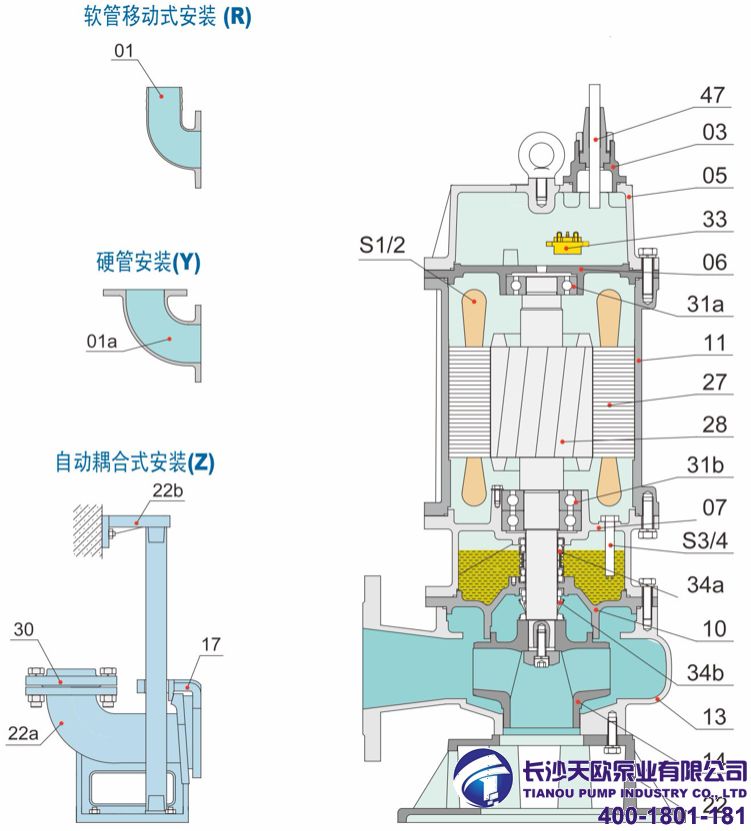

7.QW潜污泵QT/QNS泥砂泵可根据用户需要配备双导轨自动耦合安装系统,它给安装、维修带来更大方便,人可不必为此而进入污水坑。

8.能够在全扬程内使用,而保证电机不会过载。

9.有两种不同的安装方式,固定式自动耦合安装系统、移动式自由安装系统。

■ QW潜污泵QT/QNS泥砂泵使用条件

1、介质温度不超过60℃;介质重度为1~1.3kg/dm3。

2、无内自流循环冷却系统的泵,电机部分露出液面不起过1/3。

3、铸铁材质的使用范围这PH5~9。

4、使用环境海拔高度不超过1000米,超过时应在订货时提出,以便为您提供更可靠的产品。

■ QW潜污泵QT/QNS泥砂泵结构

该系列泵采用独特结构和新型机械密封,能有效地输送含有固体物和长纤维。叶轮与传统叶轮相比,该泵叶轮采用单流道或双流道形式,它类似于一截面大小相同的弯管,具有非常好的过流性,配以合理的蜗室,使得该泵具有效率高、叶轮经动静平衡试验,使泵在运行中无振动。

具有节能效果显著、防缠绕、无堵塞、自动安装和自动控制等特点。在排送固体颗粒和长纤维垃圾方面,具有独特效果。

长沙天鹅天欧工业泵品牌服务承诺:

产品在质量保证期内,对有缺陷的产品负责包修、包换、包退;所有质量问题投诉,24小时内作出答复。外派服务人员,做到故障不排除或未作出结论意见,不撤离现场。我厂所出厂的配件均为原装尺寸配件。我厂现生产的产品及配件与原有型号通用、通配,如出现安装尺寸及质量问题我们将无条件退换货,所有设备服务终身!(整机保修一年,易损件保修六个月)。

全国各区域售后部联系方式:

售后总部

湖南长沙 400-1801-181

(其他各区域售后联系方式,敬请来电索取)